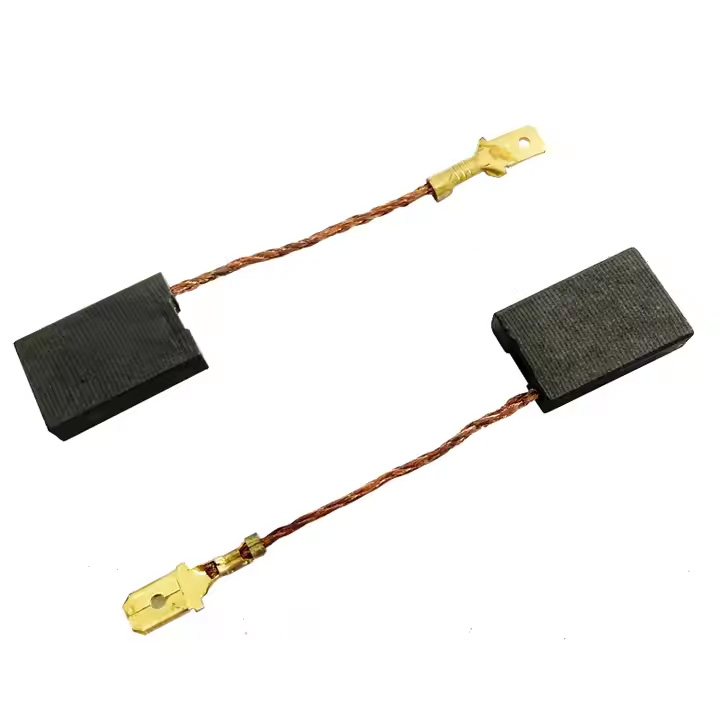

Carbon Brush for Electric Motor Plug-in / Spade Terminal 6×10×16mm

Product Overview

This premium-grade carbon brush is engineered for high-efficiency electrical contact in AC/DC motors, generators, and various power tools. Crafted with fine graphite and copper materials, it ensures low friction, high conductivity, and stable operation even in demanding environments.

Key Features

-

Efficient Power Transfer: Designed with a plug-in / spade terminal for quick, secure electrical connections, minimizing installation time and ensuring stable conductivity.

-

Premium Graphite Composition: Made from high-purity graphite, offering excellent electrical conductivity, low friction, and long service life—ideal for high-speed, high-load applications.

-

Durable Construction: Engineered for consistent performance under demanding operating conditions, reducing wear on commutators and slip rings.

-

Versatile Application: Suitable for a wide range of electric power tools, household appliances, and small motor systems requiring reliable brush-to-commutator contact.

-

Easy Replacement: Plug-in design allows fast replacement without the need for special tools or soldering, maximizing maintenance efficiency.

Typical Applications

-

Electric Drills / Grinders / Angle Cutters

-

Vacuum Cleaners / Washing Machines

-

Automotive Alternators

-

Industrial Blowers / Pumps / CNC Machinery

📐 Technical Specifications

| Parameter | Value |

|---|---|

| Brush Material | Electro-graphite |

| Dimensions | 6×10×16mm (customizable) |

| Wire Type | Copper Braided Flexible Lead |

| Wire Terminal | Faston / Spade / Customizable |

| Operating Voltage | Up to 500V |

| Operating Temp. | -40°C ~ +120°C |

| Application Motor | DC Brushed |

🧭 Carbon Brush Selection Guide

| Motor Power (kW) | Suggested Brush Size | Material Type | Lead Type |

|---|---|---|---|

| < 0.5 kW | 6x10x15 mm | Copper Graphite | Tinned Copper |

| 0.5 – 2.2 kW | 8x16x25 mm | Electrographite | Braided Copper |

| 2.2 – 7.5 kW | 12x25x32 mm | Resin-bonded Graphite | Braided Copper |

| > 7.5 kW | Custom size | High-density Graphite | Silver-plated Terminal |

💡 Customization Available

We offer full OEM/ODM support with customized size, spring tension, material composition, and terminal options. Send your drawing or sample for a quick quote.